I suppose I should delve into the layout options and pretty this up a bit. But not today, because I'm feeling pretty rubbish today and don't feel like thinking.

Well, the Mk1 air valve worked but wasn't very precise. The Mk2 didn't get a lot further. Currently on Mk3.

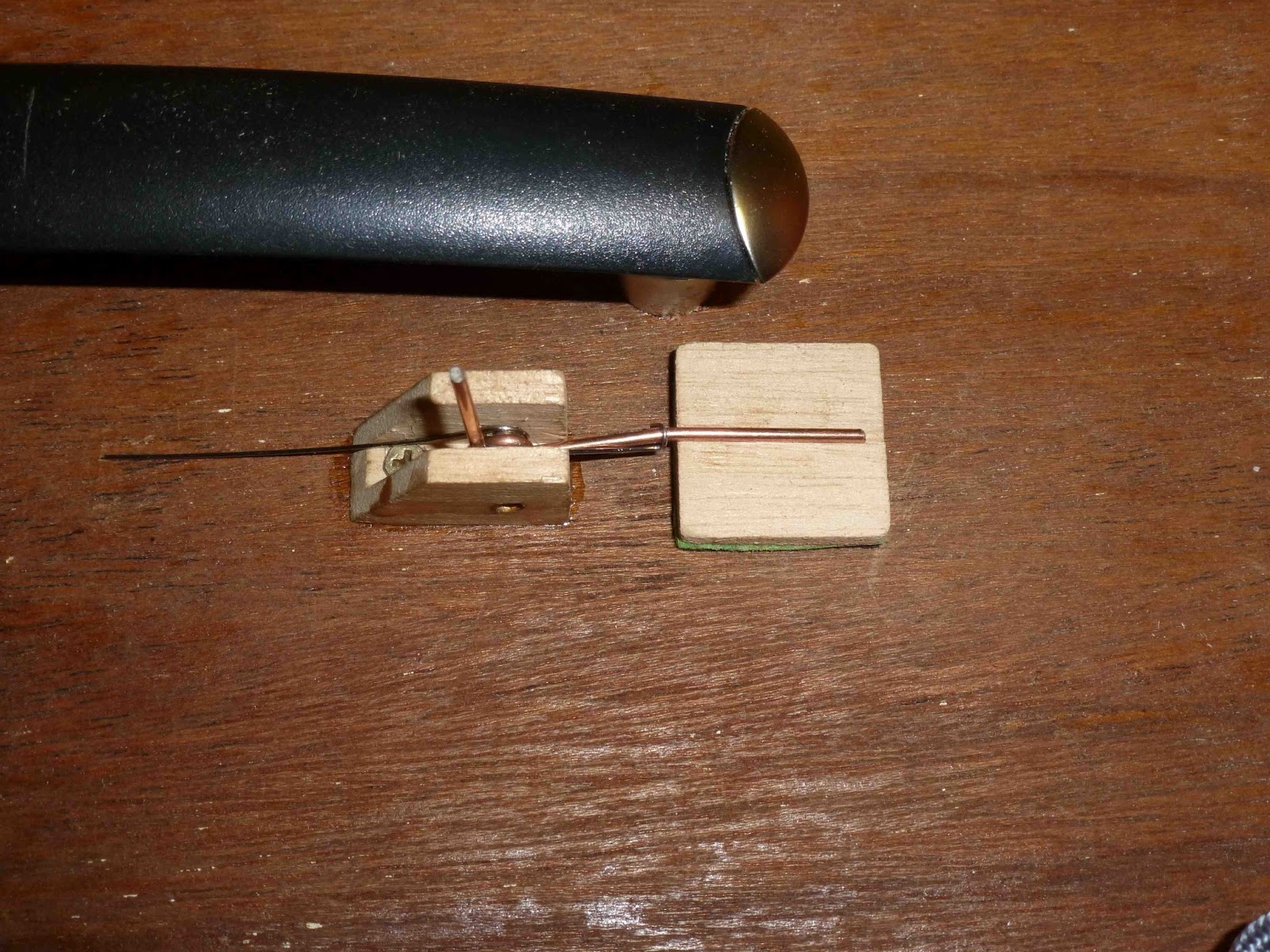

The MK3 is still WIP, but it will fit inside the bass end of a mini-melodeon.

The narrower slot on on the right guides the lever to stop it moving around too much. It is actually a tad too wide, but it's staying that way. The LH side allows a fixing screw, but it will be glued - the screw is just to keep it still while the glue dries. Lot easier than trying to clamp it. But it needs some tidying up first.

The other one is a spare in case I cock up the first one. As if :-) (I started with three spares...)

The lever is made, the spindle (3mm stainless rod) too. I need to make the spring, 0.55mm piano wire (some may recognise that gauge). Making it is fairly easy, fitting it to the spindle is a pig. Later.

I have marked out where to drill the bass casework. I think I can manage a 10mm hole, still deciding whether to make it round or oval.

Anyway, that's up to date. Nothing more will happen for a few days at least, partly because I'm suffering from a bug but mainly because the weather has turned cold and my garage isn't heated.

Melodeons - and less

Tuesday, 15 January 2013

First update. This is stuff I've already done, but the last post was long enough and it was getting late.

To tune reeds you need a tuning bench, and I've been making one for a while, when it's not been too cold in the garage. The plan was to only use material that I already had, which led to some heavier duty woodwork than first anticipated. The bellows is a PA bellows, new and unused. Slight tactical error in cutting the end frames down when removing them would have been better, but whatever.

Nearly finished when some bloke called Lester, from Wendover, revealed to the world his newly fitted air valve for his tuning table. Seemed a good idea, but I didn't want to nick one from a melodeon, didn't want to spend nearly £20 buying one, so I decided to make one.

Some piccies below. Buying would have been more sensible, but less fun. It's not very pretty, not very precise, but it works plenty well enough.

It works surprising well and holds pressure.

(I though I had some cupboard handles lying around, but couldn't find any, so the black handle in the pic came from B&Q for about £3. )

Well, useful facility for the mini-melodeon but not strictly relevant, you might think. No so. The mini-melodeon needs an air valve... and this one operates like a Hohner air valve.

To tune reeds you need a tuning bench, and I've been making one for a while, when it's not been too cold in the garage. The plan was to only use material that I already had, which led to some heavier duty woodwork than first anticipated. The bellows is a PA bellows, new and unused. Slight tactical error in cutting the end frames down when removing them would have been better, but whatever.

Nearly finished when some bloke called Lester, from Wendover, revealed to the world his newly fitted air valve for his tuning table. Seemed a good idea, but I didn't want to nick one from a melodeon, didn't want to spend nearly £20 buying one, so I decided to make one.

Some piccies below. Buying would have been more sensible, but less fun. It's not very pretty, not very precise, but it works plenty well enough.

Frame, lever and spring. And hole.

The pad - deliberately oversize, because the registration is a bit wobbly. It is faced with some felt and leather. Overkill, but good practice

Pad glued on, with some cotton material and PVA. Not the neatest job. A small cylinder of white plastic completes the handle, but I forgot to photograph it.

It works surprising well and holds pressure.

(I though I had some cupboard handles lying around, but couldn't find any, so the black handle in the pic came from B&Q for about £3. )

Well, useful facility for the mini-melodeon but not strictly relevant, you might think. No so. The mini-melodeon needs an air valve... and this one operates like a Hohner air valve.

Sunday, 13 January 2013

It's a good job I'm used to looking at big blank sheets of paper - or even areas of screen. Of course, now I've written this, it isn't blank any more.

Why am I doing this? Daft idea. Well, mostly to write about another daft idea.

I am - slowly and painfully - learning to play a melodeon, and more slowly (at present) concertina. At one point I bought, as many do, one of those little red, white and blue Chinese toy boxes off of Ebay.

Well, it's fun, it's about as airtight as a colander, it's in C (roughly) and it's far too small for my hands. That - apart, I hope, from the first bit - is about to change. How? Well, here's the plan.

1) Add a proper air button. Well, at least one that works like a Hohner air valve. If you don't know what a Hohner air valve is, nothing much after this point will make much sense to you anyway.

2) Seal the damn thing. The gussets and corners are made of a porous material and make the existing air valve largely superfluous. I have some thin leather, from Concertina Spares, poised waiting to go. Although, to be fair, very thin leather doesn't really poise that well.

3) Retune to G Major. Ah. The interesting bit. Using the original reeds. Even more interesting. And possibly not permanent. But, this is just the plan. Other reeds are available.

4) Ditto the basses/chords. Also move them down a peg, since the bottom button is presently the air button. New woodwork required, methinks. Also one reed refuses to play, but haven't looked in detail yet. And the thirds might be notional, need to get them out and have a play. The reeds. Oh, and add a unisonoric C bass on the top button. So, maybe not so major, but still G.

5) Remake the straps. I have some old melodeon straps (i.e. real melodeon straps. Real straps, from real melodeons) that are old, tired and too short. (For those who know me, just think it, don't say it.). I have the technology to make them shorter and thinner. (For myself, I don't need shorter and thinner will not involve a very sharp paring knife. Tired I have to live with, especially on Mondays. )

You may have realised by now that I am as interested in what makes them work as I am in learning to play. But there is a reason, for the toy box, it is something to take and practice on when waiting in the car to collect people, maybe at lunchbreaks, places where a real one is too big to take. So it will be used.

Why am I doing this? Daft idea. Well, mostly to write about another daft idea.

I am - slowly and painfully - learning to play a melodeon, and more slowly (at present) concertina. At one point I bought, as many do, one of those little red, white and blue Chinese toy boxes off of Ebay.

Well, it's fun, it's about as airtight as a colander, it's in C (roughly) and it's far too small for my hands. That - apart, I hope, from the first bit - is about to change. How? Well, here's the plan.

1) Add a proper air button. Well, at least one that works like a Hohner air valve. If you don't know what a Hohner air valve is, nothing much after this point will make much sense to you anyway.

2) Seal the damn thing. The gussets and corners are made of a porous material and make the existing air valve largely superfluous. I have some thin leather, from Concertina Spares, poised waiting to go. Although, to be fair, very thin leather doesn't really poise that well.

3) Retune to G Major. Ah. The interesting bit. Using the original reeds. Even more interesting. And possibly not permanent. But, this is just the plan. Other reeds are available.

4) Ditto the basses/chords. Also move them down a peg, since the bottom button is presently the air button. New woodwork required, methinks. Also one reed refuses to play, but haven't looked in detail yet. And the thirds might be notional, need to get them out and have a play. The reeds. Oh, and add a unisonoric C bass on the top button. So, maybe not so major, but still G.

5) Remake the straps. I have some old melodeon straps (i.e. real melodeon straps. Real straps, from real melodeons) that are old, tired and too short. (For those who know me, just think it, don't say it.). I have the technology to make them shorter and thinner. (For myself, I don't need shorter and thinner will not involve a very sharp paring knife. Tired I have to live with, especially on Mondays. )

You may have realised by now that I am as interested in what makes them work as I am in learning to play. But there is a reason, for the toy box, it is something to take and practice on when waiting in the car to collect people, maybe at lunchbreaks, places where a real one is too big to take. So it will be used.

Subscribe to:

Posts (Atom)